Precision aluminum casting techniques that maximize production efficiency

Wiki Article

Discovering the Role of Factory Solutions in Progressing Modern Design Solutions

Foundry services are necessary in shaping contemporary design services - Aluminum Casting Company. They connect the gap between conventional manufacturing strategies and the needs of modern markets. With innovations in automation and sustainability, foundries are advancing to meet the needs of sectors such as aerospace and automotive. This transformation raises questions regarding the effects for products, processes, and future innovations. What difficulties and chances lie in advance for shop services in this rapidly changing landscape?The Advancement of Foundry Providers in Design

The integration of computer-aided style (CAD) and simulation software application has actually transformed the design and production procedures, making it possible for shops to create intricate geometries with higher accuracy. The change towards eco-friendly practices has actually led to the adoption of greener technologies and reusing efforts within factories. As markets significantly prioritize personalization and quick prototyping, foundry solutions have broadened their capabilities, ensuring they continue to be necessary contributors to the design landscape. This development emphasizes the shop's important role in supporting improvements across different sectors, consisting of vehicle, aerospace, and power.

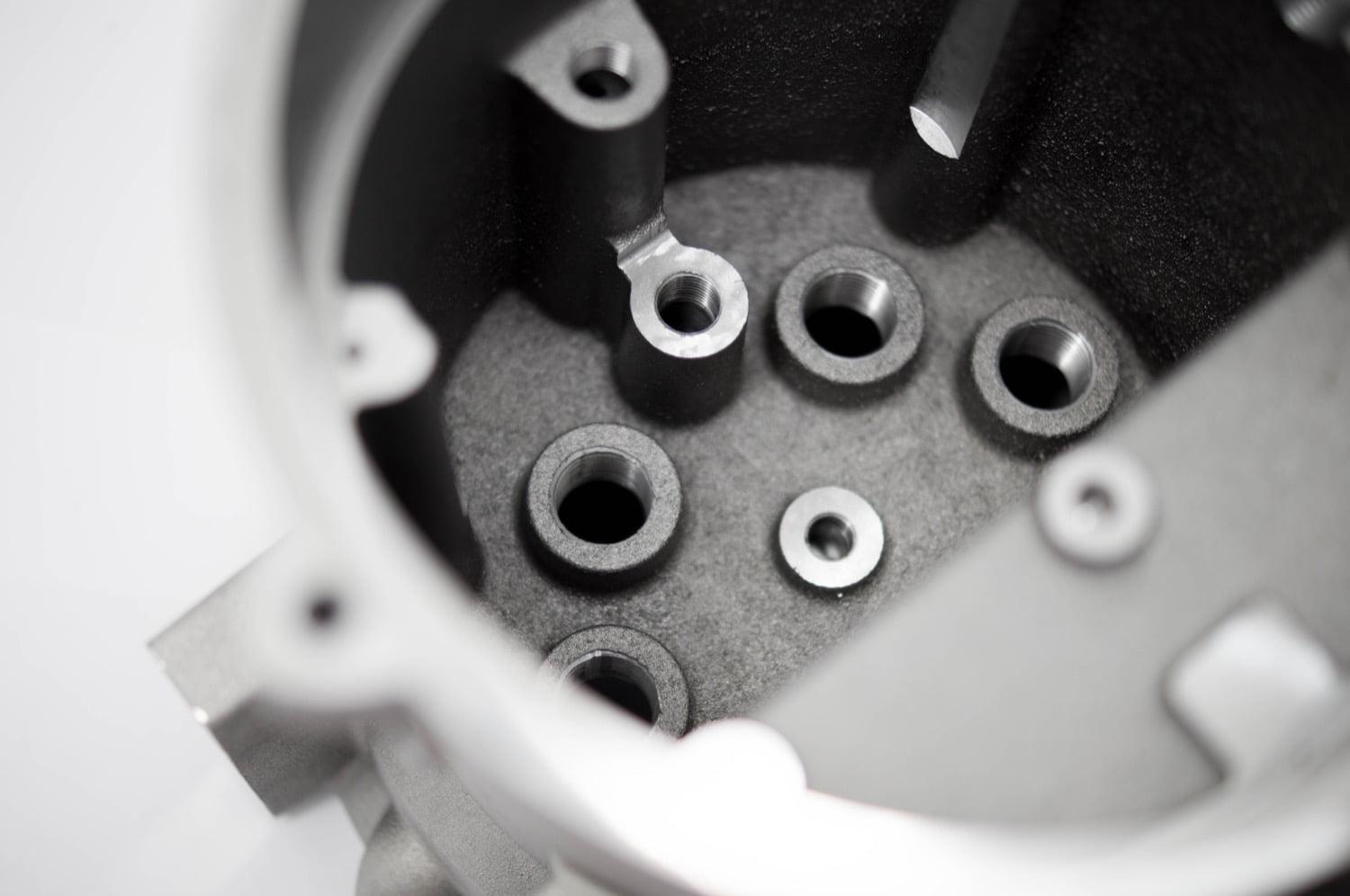

Trick Processes and Methods in Modern Foundries

Modern shops employ a variety of essential procedures and methods that boost the efficiency and top quality of steel spreading. Amongst these, sand casting continues to be common because of its adaptability and cost-effectiveness. Making use of sophisticated modern technologies, such as computer-aided layout (CAD) and computer-aided production (CAMERA), permits exact modeling and manufacturing, making certain high precision in part measurements. Furthermore, financial investment spreading is preferred for creating intricate geometries with excellent surface area coatings.In addition, automation and robotics improve manufacturing rate and uniformity while decreasing labor expenses. Methods like additive production are increasingly integrated to create elaborate mold and mildews and cores, consequently lessening product waste. The application of thermal evaluation help in optimizing casting processes by controlling and anticipating solidification actions. Jointly, these processes and methods exhibit just how contemporary foundries are adjusting to satisfy the needs of modern design obstacles, ensuring superior product top quality and functional performance.

The Significance of Products Selection in Foundry Providers

Selecting the ideal materials is vital in foundry solutions, as it directly influences the mechanical properties, durability, and general efficiency of the end product. Various materials possess one-of-a-kind features, such as tensile stamina, corrosion resistance, and thermal stability, which have to line up with the designated application of the cast elements. Metals like aluminum and steel are commonly chosen for their strength-to-weight ratio, while alloys can improve particular efficiency traits.The option process entails considering aspects such as expense, manufacturability, and accessibility, which can especially influence project timelines and spending plans. In addition, innovations in product science make it possible for the development of innovative compounds and specialized alloys that deal with arising design challenges. A comprehensive understanding of product residential or commercial properties and their ramifications is important for designers and shop specialists to accomplish effective end results in their jobs. This careful selection process inevitably boosts the integrity and performance of completion products.

Factory Providers in Aerospace and Automotive Applications

Foundry services play an essential function in the aerospace and automotive sectors, where accuracy and performance are vital. These industries count greatly on the manufacturing of complicated components that have to meet extensive quality criteria and stand up to extreme problems. Foundries offer essential services such as spreading, machining, and completing, making certain parts are lightweight yet robust, important for improving fuel efficiency and security.In aerospace, foundry services add to the manufacturing of wind turbine blades, engine components, and structural components, every one of which need high-performance materials and intricate layouts. Similarly, in the auto field, factories supply engine blocks, framework elements, and transmission instances, focusing on durability and weight reduction.

Advanced factory strategies, consisting of additive manufacturing and accuracy spreading, are progressively utilized to meet the details demands of these markets. By offering customized remedies, factory solutions assist drive advancement and preserve competitive advantages in the fast-evolving aerospace and vehicle landscapes.

Advancements Driven by Factory Capabilities

Many innovations in engineering are fueled by the sophisticated capacities of shop solutions. These services make it possible for the production of complex geometries and high-performance products that are important for contemporary applications. Additive production, typically recognized as 3D printing, has seen substantial improvements through foundry strategies, permitting for the fast prototyping of detailed layouts. In addition, the capability to cast lightweight alloys has changed markets such as aerospace and automotive, bring about improved fuel performance and efficiency.Foundries are increasingly incorporating wise innovations, such as automation and data analytics, to boost manufacturing performance and quality control. These advancements not just minimize waste yet likewise enable customization at official statement scale, fulfilling the specific requirements of customers. By leveraging sophisticated factory abilities, engineers can explore new frontiers in item style and performance, inevitably driving development throughout various fields and establishing a structure for future developments.

Future Fads in Foundry Solutions and Engineering Solutions

The future of factory solutions is formed by arising patterns such as sustainable manufacturing practices, which prioritize environmental responsibility. Automation and wise innovations are readied to boost effectiveness and accuracy, while boosting personalization and flexibility will certainly meet the developing needs of clients. As these fads develop, they will redefine the landscape of design services in the foundry field.

Lasting Production Practices

As sectors progressively focus on ecological duty, sustainable manufacturing methods within shop services are coming to be necessary to modern engineering solutions. These practices concentrate on decreasing waste, minimizing energy intake, and utilizing eco-friendly materials throughout the manufacturing process. By implementing techniques such as recycling scrap metal and optimizing melting procedures, shops can especially decrease their carbon impact. Furthermore, the fostering of life cycle evaluations enables makers to assess the environmental effect of their items from creation to disposal. Collaborating with suppliers committed to sustainability additionally improves the efficiency of these initiatives. Ultimately, welcoming lasting production not only lines up with global environmental objectives yet also fosters development and competition in the rapidly progressing design landscape.Automation and Smart Technologies

While many industries are accepting technological improvements, factory solutions are experiencing a significant makeover via automation and smart modern technologies. The combination of robotics and automated systems boosts production effectiveness, decreases human mistake, and accelerates the manufacturing procedure. Smart technologies, such as IoT and AI, enable real-time monitoring and anticipating upkeep, which enhance functional performance and reduce downtime. These advancements facilitate data-driven decision-making, allowing shops to react quickly to market needs and enhance item quality. Furthermore, automation reduces labor prices and boosts work environment safety and security by handling unsafe tasks. As shop solutions remain to embrace these advancements, they are poised to redefine engineering remedies, bring about increased competitiveness and sustainability in the production market.Modification and Flexibility Patterns

Emerging trends in shop solutions significantly emphasize customization and adaptability to meet distinct customer requirements. This shift mirrors a wider demand for tailored design services that adapt to particular project requirements and industry standards. Business are spending in sophisticated innovations, such as additive manufacturing and electronic modeling, allowing them to create personalized elements successfully and cost-effectively. Therefore, foundries are relocating far from one-size-fits-all strategies, providing customers the capability to change styles and products in real-time. In addition, cooperation between design groups and factory solutions is becoming much more incorporated, cultivating technology and increasing time-to-market. This trend not only enhances product efficiency however also sustains sustainability by minimizing waste through exact manufacturing processes.Regularly Asked Questions

What Are the Normal Prices Related To Foundry Services?

Common costs related to foundry solutions include material expenses, labor fees, devices usage charges, and overhead costs - Aluminum Casting Company. These expenditures can differ widely based on job complexity, volume, and particular needs of the design service involvedExactly how Long Does the Shop Refine Typically Take?

The foundry process usually takes anywhere from a number of weeks to a couple of months, relying on aspects such as intricacy, product needs, and manufacturing volume, which can greatly affect timelines and general task distribution.What Industries Advantage Most From Foundry Solutions?

Industries such as automotive, aerospace, and construction benefit significantly from foundry services. These sectors rely upon precision spreading and useful site metal construction to produce complex elements, improving product efficiency and operational efficiency in their particular applications.What Certifications Should Factories Have?

Shops need to possess certifications such as ISO 9001 for high quality administration, ISO 14001 for environmental monitoring, and read the article certain sector accreditations like AS9100 for aerospace or IATF 16949 for vehicle, making certain compliance and quality control.How Do Foundries Make Certain High Quality Control in Their Procedures?

Factory services are vital in forming contemporary design options. As design techniques have progressed, the duty of factory solutions has actually transformed substantially to fulfill progressing industry needs. As markets increasingly focus on modification and fast prototyping, foundry services have actually broadened their capacities, ensuring they remain important contributors to the design landscape. As sectors progressively prioritize ecological duty, lasting manufacturing techniques within factory solutions are ending up being essential to contemporary engineering services. In addition, collaboration between design groups and foundry services is coming to be a lot more incorporated, cultivating technology and accelerating time-to-market.

Report this wiki page